Here is how Helmee inspects glossy items

Our Japanese distributor states “Helmee and your customer’s relationships are like doctor and patients.”.

It is true as we have seen many customers who have challenges and pain in their inspection process and our task is to help them. Helmee automates inspection process for high gloss items. Usually this inspection process is done by people while many manufacturing processes at factories are nowadays automated. It has been causing headache to our customers as finding various kinds of defects from shiny surfaces is challenging for people. This blog explains how we are capable to serve our “patients”.

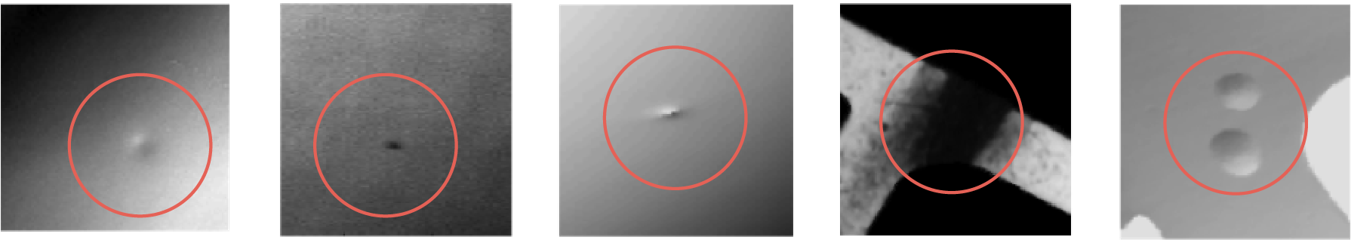

Helmee has various kinds of image types

Our engineers have been developing different types of images. Ideally different image types make the different defects stand out. According to our engineers, there are two types of images mainly. One is reflection quality type of image which sees reflectiveness on the surface. Another one is shape type of image which sees geometry variation of the surface. Usually most of the defects are not visible in traditional gray scale image while they are clearly visible in other image types developed by Helmee engineers. At this moment, we use more than 10 kinds of image types.

Tools will be applied to images and analyze

We have been testing out all kinds of components and parts from our customers. They challenge us with all kinds of defects when requesting our help. Some examples of common defects we receive are dots, scratch, missing coating, dent and burn mark etc… Those defects are clearly visible in many image types of Helmee CSD®. Our skillful engineers made tools to distinguish the defects from those images. The setting of the tools is flexibly adjustable so that we can follow our customers’ criteria for defects. Furthermore, customers can fine tune the tools by themselves.

More and more…!

Helmee CSD® has been able to find all kinds of defects and its capabilities is expanding continuously as customers present us the new types of defects. Almost like magically our engineers can make new tools to find those new defects that they have not seen before. So, the more we receive the defected parts, the more we learn and better we serve you. To remove your pain and headache, please contact us and send us your glossy items for the feasibility study. For sure, we can help to improve your quality inspection process.

Read more articles

To learn more about CSD® technology and automated inspection of highly reflective products, please contact us.

We look forward to discussing the subject with you further!

Follow us on social media