The Covered Stereo Deflectometry technology

PERFECTING THE FUTURE

CONTACT US

Hexagon CSD® (Covered Stereo Deflectometry) technology based machine vision systems are designed to visually inspect glossy – mirror like objects. CSD® is the only available technology in the market that can simultaneously inspect surface properties and 3D shape of a glossy object.

Glossy surfaced parts are typically inspected manually by humans due to lack of automatic tools so far. Those products are often produced in large quantities making the inspection work extremely difficult and monotonic due to large volume and fast pace. This leads into quality deviation caused by inspection process or workers. With Hexagon CSD® you can tune the level of acceptance in inspection.

Covered

Covered comes from fact that we use dome covering the part when doing the inspection. The dome is there to spread light equally to part surface working as a diffuser. By changing the dome, we can control the amount of the light going through. The other task for the dome is to collect the light reflections from the light surface. Typically the part is curved which means the light reflects to multiple directions and we can capture reflections with dome.

Stereo

Stereo means we use multiple cameras, typically three. The parts are 3D shape. In order to capture reflections we must have multiple viewpoints enabling 3D shapes to be inspected. While having different view points the three cameras are still overlapping each other to ensure the complete surface will be covered. With three cameras we can also simultaneously observe different sides of the parts.

Deflectrometry

We use deflectometry which is common technology and well known, originally it was used to amplify radio waves. Sinusoidal light patterns are waves as well, revealing defects on the surface. Now the deflectometry amplifies the light waves making even the smallest defects visible for the system.

THE EYES – Camera

The Hexagon system is built around three high-resolution, high-speed cameras and Hexagon’s own optical arrangement, which is part of the CSD® (Covered Stereo Deflectometry) technology. The other part of the CSD® is an inhouse, Hexagon built software, which can create models of the surface properties, such as shape and reflection quality in addition to the typical grey-scale images from the cameras. For illumination, we use special long life light projector based on lasers, leds and micro-mirror technology.

THE BRAIN – Software

The system is enclosed into an industry grade frame and covers that are designed for long life time and easy to maintain. Hexagon CSD® system software is running in a high end PC with the most powerful processors available, to squeeze the image processing time into minimum. The system software includes all the tools and features needed to operate, report, analyse the inspection process and to teach new parts to be inspected, just pointing and clicking. No programming is needed!

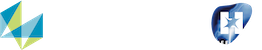

THE HANDS – Robots

Hexagon CSD® is integrated into a robot cell that has two robot arms and a tray buffer for part handling. Robots can be industrial or collaborative. The robots move the parts to the inspection system’s field of view quickly and sort them according to the inspection result. Hexagon’s robotized CSD® system can inspect over 10 million parts in a year.